Product Costs Types of Costs, Examples, Materials, Labor, Overhead

Whereas, variable direct manufacturing overhead costs include indirect labor, indirect material and utilities. Though most of these costs are self-evident, indirect material costs are unique because these costs are not essential to the physical production of the product. Factory overhead – also called manufacturing overhead, refers to all costs other than direct materials and direct labor spent in the production of finished goods.

Nonmanufacturing Overhead (Explanation Part

Another commonly used term for manufacturing costs is product costs, which also refer to the costs of manufacturing a product. As a result, the company decided to outsource production to a contract manufacturing company (a company that enters into a contract with the manufacturer to make certain components) instead of assembling components in-house. Start by making a list of all the direct materials that are used to make the specific product and obtain the cost information for the direct materials you have identified.

Direct Labor vs. Labor Cost & Manufacturing

As you can see, by collecting cost data and calculating it accurately, businesses can optimize cost management and set the right price for their products to gain a competitive advantage. As a result, the steel manufacturing company was able to achieve a 10% reduction in manufacturing nonmanufacturing costs include costs and save €1 million (approximately $1.7 million) annually. Cost control, according to Fabrizi, is one of the top benefits of calculating manufacturing costs. At this stage, the completed products are transferred into the finished goods inventory account.

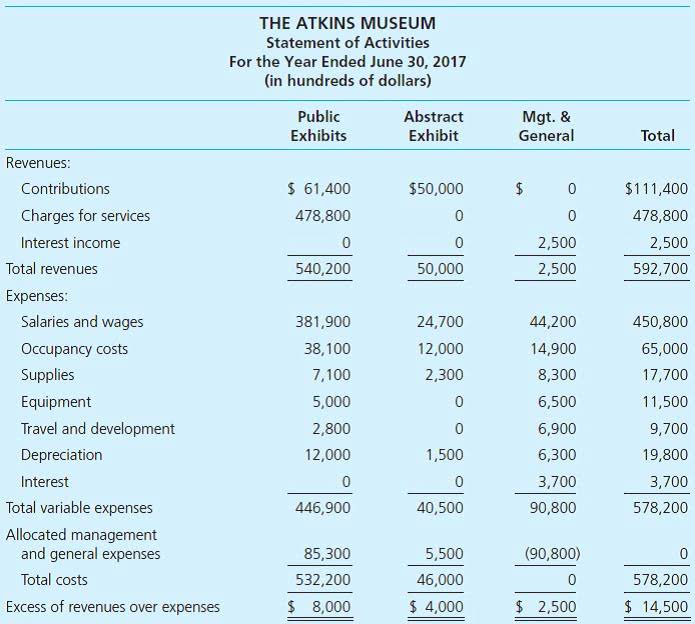

Financial Reporting vs. Individual Products and Customers

- Nonmanufacturing costs play a significant role in strategic decision-making, influencing everything from pricing strategies to investment decisions.

- Tracking the number of hours each employee works on the production line can be tricky.

- Product costs are treated as inventory (an asset) on the balance sheet and do not appear on the income statement as costs of goods sold until the product is sold.

- Rather, nonmanufacturing expenses are reported separately (as SG&A and interest expense) on the income statement for the accounting period in which they are incurred.

- Selling expenses include costs related to marketing, advertising, and distribution.

- For instance, a company might notice that its advertising costs peak during the holiday season, prompting it to allocate more funds to marketing during this period while scaling back in quieter months.

Manufacturing costs are the costs of materials plus the costs to convert the materials into products. All manufacturing costs must be assigned to the units produced in order https://www.bookstime.com/ for a company’s external financial statements to comply with U.S. By calculating manufacturing costs, companies can clearly understand the true cost of making a product.

- Other manufacturing overhead items are factory building rent, maintenance and depreciation for production equipment, factory utilities, and quality control testing.

- Now that you are familiar with the components that constitute manufacturing costs, let’s move on to the process of calculating these expenses.

- Each of the T-accounts traces the movement of the raw materials from inventory to work in process.

- For instance, a company might invest in digital marketing campaigns or hire sales personnel to boost product visibility and drive sales.

- According to the book Manufacturing Cost Estimating, the benefits of calculating the costs of manufacturing range from guiding investment decisions to cost control.

For example, a tech company might allocate substantial funds to develop new software features or hardware improvements. While these costs do not contribute to immediate production, they are crucial for long-term growth and sustainability. In today’s manufacturing environment, when orders are filled in hours and days rather than weeks and months, it is critical for any enterprise to stay on top of these costs at all times. For over twenty-five years their time-tested technology has been giving businesses the edge over their competition.

For the past 52 years, Harold Averkamp (CPA, MBA) hasworked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. Therefore, always consult with accounting and tax professionals for assistance with your specific circumstances. For the past 52 years, Harold Averkamp (CPA, MBA) has worked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. Direct labor would include the workers who use the wood, hardware, glue, lacquer, and other materials to build tables. The resulting unit costs are used for inventory valuation and for the calculation of the cost of goods sold.

AccountingTools

The company engaged a consulting firm to help them find out what factors were driving up manufacturing costs. By looking at the historic data on employee timesheets and purchasing costs, the firm was able to understand the areas that were increasing the total manufacturing costs. Whether you’re just starting your own manufacturing business or are looking to venture into the field of cost accounting, understanding manufacturing costs and knowing how to accurately calculate them is crucial for success. MasterCraft records these manufacturing costs as inventory on the balance sheet until the boats are sold, at which time the costs are transferred to cost of goods sold on the income statement. Direct material costs are the costs of raw materials or parts that go directly into producing products.

Example #1: Direct materials

Finally it will also let you run “what-if” studies in order to find the best and most efficient ways to run your business. SMe Software’s complete Manufacturing Management Software is highly configurable, completely integrated business software for the small to mid-size manufacturer. Nonmanufacturing overhead costs are the company’s selling, general and administrative (SG&A) expenses plus the company’s interest expense. Direct labor costs include the wages and benefits paid to employees directly involved in the production process of goods or products. Be sure to allocate overhead costs to the respective cost centers (specific departments, processes, or machines in the manufacturing facility that contribute to the manufacturing costs).

- Previous article:

- The Pros and Cons of Choosing WordPress for your Website CMS

- Next article:

- 155+ Tatuagens De Pin-up Estilo Retrô Masculinas E Feminina